Geotextiles (Educational Research)

Hsu-Yeh Huang and Xiao Gao

Introduction

According to the historical record, it is believed that the first applications of geotextiles were woven industrial fabrics used in 1950's. One of the earliest documented cases was a waterfront structure built in Florida in 1958. Then, the first nonwoven geotextile was developed in 1968 by the Rhone Poulence company in France. It was a comparatively thick needle-punched polyester, which was used in dam construction in France during 1970.

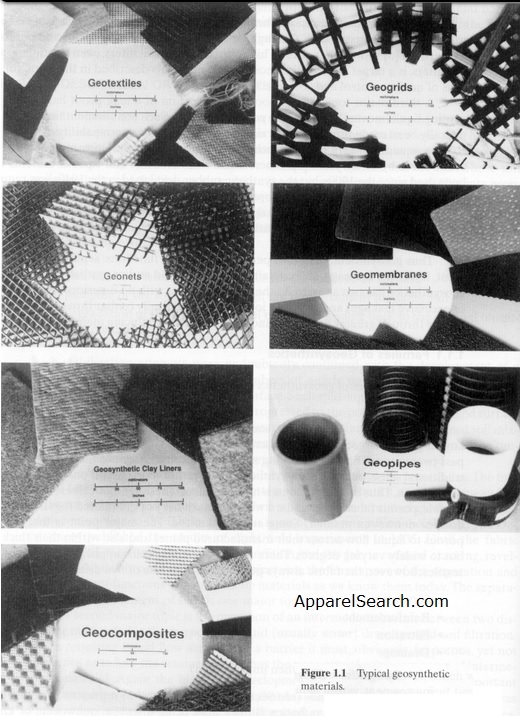

In fact, the geotextile is one of the members of the geosynthetic family. Those members include the following items as shown in Fig.1: [1-2]

- Geogrids

- Geonets

- Geotextiles

- Geomembranes

- Geosynthetic Clay Liners

- Geopipe

- Geocomposites

What is geotextile?

As we know, the prefix of geotextile, geo, means earth

and the

textile

means fabric. Therefore, according to the definition of

ASTM 4439, the geotextile is defined as follows:[1]

"A permeable geosynthetic comprised solely of textiles. Geotextiles are used with foundation, soil, rock, earth, or any other geotechnical engineering-related material as an integral part of human-made project, structure, or system."

The ASAE (Society for Engineering in Agricultural, Food, and Biological Systems) defines a geotextile as a "fabric or synthetic material placed between the soil and a pipe, gabion, or retaining wall: to enhance water movement and retard soil movement, and as a blanket to add reinforcement and separation." A geotextile should consist of a stable network that retains its relative structure during handling, placement, and long-term service. Other terms that are used by the industry for similar materials and applications are geotextile cloth, agricultural fabric, and geosynthetic. [ 2 ]

The type of Geotextile

[ 1 ]In general, the vast majority of geotextiles are made from polypropylene or polyester formed into fabrics as follows:

- Woven monofilament

- Woven multifilament

- Woven slit-film monofilament

- Woven slit-film multifilament

- Nonwoven continuous filament heat bonded

- Nonwoven continuous filament needle-punched

- Nonwoven staple needle-punched

- Nonwoven resin bonded

- Other woven and nonwoven combinations

- Knitted

Figure 2-1 Non-woven (left) and Fig 2-2 woven (right) geotextile fabrics [7]

Raw material of Geotextiles

The four main polymer families most widely used as the raw material for geotextiles are:

- Polyester

- Polyamide

- Polypropylene

- Polyethylene

The oldest of these is polyethylene, which was discovered in 1931 in the research laboratories of the ICI. Another group of polymers with a long production history is the polyamide family, the first of which was discovered in 1935.The next oldest of the four main polymer families relevant to geotextile manufacture is polyester which was first announced in 1941.The most recent polymer family relevant to geotextiles to be developed was polypropylene, which was discovered in 1954. The comparative properties of these four polymer are shown in very general items in Table 1.[3]

Table 1

| Polyester | Polyamide | Polypropylene | polyethylene | |

| Strength |

H |

M |

L |

L |

| Elastic modulus |

H |

M |

L |

L |

| Strain at failure |

M |

M |

H |

H |

| Creep |

L |

M |

H |

H |

| Unit weight |

H |

M |

L |

L |

| Cost |

H |

M |

L |

L |

| Resistance to: | ||||

|

U.V. light stabilized |

H |

M |

H |

H |

| unstabilized |

H |

M |

M |

L |

| Alkalis |

L |

H |

H |

H |

| Fungus, vermin |

M |

M |

M |

H |

| Fuel |

M |

M |

L |

L |

| Detergents |

H |

H |

H |

H |

H: High M: Medium L: Low

The basic properties of geotextiles [

1]The properties of polymer material are affected by its average molecular weight (MW ) and its statistical distribution. Increasing the average MW results in increasing:

- tensile strength

- elongation

- impact strength

- stress crack resistance

- heat resistance

Narrowing the molecular weight distribution results in:

- increased impact strength

- decreased stress crack resistance

- decreased processability

Increasing crystallinity results in:

- increasing stiffness or hardness

- increasing heat resistance

- increasing tensile strength

- increasing modulus

- increasing chemical resistance

- decreasing diffusive permeability

- decreasing elongation or strain at failure

- decreasing flexibility

- decreasing impact strength

- decreasing stress crack resistance

Market activity

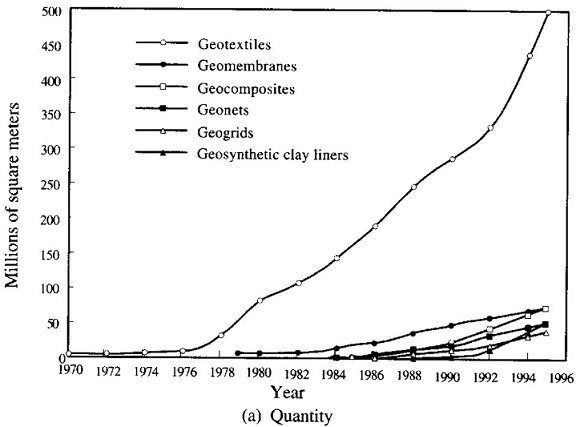

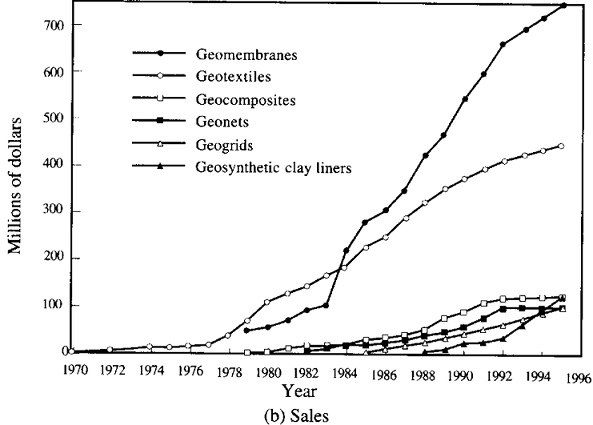

To say that the market activity of geosynthetics in the geotechnical, transportation, and environmental areas is strong is decidedly an understatement. To obtain an insight into the vitality of geosynthetics, note the curves in the graphs in Fig.3-1 and 3-2. The curves in Fig. 3-1 gives the estimated amount of geosynthetics used in North America over the years

Fig. 3-1

Fig 3-2

(geopipe is not shown ), while the curve in Fig 3-2 gives the estimated in-place expenditures of these products. Used in the calculations were the data for 1995 (note that the values are in millions of square meters and millions of dollars ): [ 1 ]

Geotextiles 500 Mm2 @ $ 0.9 / m2 = $ 450 M

Geogrids 40 Mm2 @ $ 2.50 / m2 = $ 100 M

Geonets 50 Mm2 @ $ 2.00 / m2 = $ 100 M

Geomembranes 75 Mm2 @ $ 10.00 / m2 = $ 750 M

Geosynthetic clay linears 50 Mm2 @ $ 2.5 / m2 = $ 125 M

Geocomposites 25 Mm2 @ $ 5.00 / m2 = $ 125 M

Geo-others 5 Mm2 @ $ 4.00 / m2 = $ 20 M

Total ( 1995 ) $ 1670 M

The basic function of geotextile

Geotextiles form one of the two largest groups of geosynthetics. Their rise in growth during the past fifteen years has been nothing short of awesome. They are indeed textiles in the traditional sense, but consist of synthetic Fibers rather than natural ones such as cotton, wool, or silk. Thus biodegradation is not a problem. These synthetic Fibers are made into a

flexible, porous fabric by standard weaving machinery or are matted together in a random, or nonwoven, manner. Some are also knit. The major point is that they are porous to water flow across their manufactured plane and also within their plane, but to a widely varying degree. There are at least 80 specific applications area for geotextiles that have been developed; however, the fabric always performs at least one of five discrete functions:

- Separation [ 4 ]

- Drainage :

- Filtration :

- Reinforcement

Geotextiles function to prevent mutual mixing between 2 layers of soil having different particle sizes or different properties. Table 2 shows the required properties for separation:

Figure 4. Illustration of a geotextile fabric separating a gravel layer from the underlying soil material[7]

Table 2 The required properties for Separation [ 4 ]

| Mechanical | hydraulic | Long-term performance | |

| During installation | Impact resistance Elongation at break |

Apparent opening size ( A.O.S.) Thickness |

UV resistance |

| During construction | Puncture resistance Elongation at break |

Apparent opening size ( A.O.S.) Thickness |

Chemical stability UV resistance |

| After completion of construction | Puncture resistance Tear propagation resistance Elongation at break |

Apparent opening size ( A.O.S.) Thickness |

Chemical stability Resistance to decay |

The function of drainage is to gather water, which is not required functionally by the structure, such as rainwater or surplus water in the soil, and discharge it.[ 4 ]

Fig. 5 Drainage [9]

Table 3. The required properties for drainage: [ 4 ]

| Mechanical | Hydraulic | Long-term performance | |

| Permanent drainage function | Influence of normal overburden pressure | Permeability Thickness Apparent opening size (A.O.S.) |

Chemical properties of water and soil Chemical stability Decay resistance |

| Temporary drainage function | Influence of normal overburden pressure | Permeability

Thickness Apparent opening size (A.O.S.) |

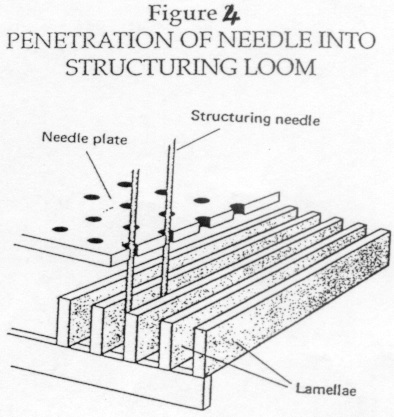

Filtration involves the establishment of a stable interface between the drain and the surrounding soil. In all soils water flow will induce the movement of fine particles. Initially a portion of this fraction will be halted at the filter interface; some will be halted within the filter itself while the rest will pass into the drain.

The geotextile provides an ideal interface for the creation of a reverse filter in the soil adjacent to the geotextile. The complex needle-punched structure of the geotextile provides for the retention of fine particles without reducing the permeability requirement of the drain. [5]

Fig.6 Filtration [5]

Table 4. The required properties for Filtration: [4 ]

| Mechanical filter stability | Hydraulic filter stability | Long-term performance | |

|

Permanent filter function |

A.O.S. Thickness |

Geotextile permeability |

Chemical properties of water and soil Chemical stability Decay resistance |

|

Temporary filter function |

A.O.S. Thickness |

Geotextile permeability |

Due to their high soil fabric friction coefficient and high tensile strength, heavy grades of geotextiles are used to reinforce earth structures allowing the use of local fill material.

Fig. 7 Reinforcement [9]

Table 5. The required properties for reinforcement:[4]

| Mechanical | Hydraulic | Long-term performance | |

| Base failure | Shear strength of bonding system | Hydraulic boundary conditions | Chemical and decay resistance |

| Top failure | Tensile strength of geotextile Geotextile/ soil friction |

Hydraulic boundary conditions | Chemical and decay resistance |

| Slope failure | Tensile strength of geotextile Geotextile/ soil friction |

Creep of the geotextile/ soil system Chemical and decay resistance |

- Protection:

Erosion of earth embankments by wave action, currents and repeated drawdown is a constant problem requiring the use of non-erodable protection in the form of rock beaching or mattress structures. Beneath these is placed a layer of geotextile to prevent leaching of fine material. The geotextile is easily placed, even under water.[6]

Fig.8 Protection [6]

Table 6. The required properties for protection [4]

| Mechanical | Long-term performance | |

| Tunnel construction | Burst pressure resistance Puncture resistance Abrasion resistance |

Chemically stable: pH=2-13 Decay resistance |

| Landfill and reservoir geomembrane construction | Puncture resistance Burst pressure resistance Friction coefficient |

Chemically stable: pH=2-13 Decay resistance |

| Flat roof construction | Puncture resistance | Chemical compatibility |

Application

Case ( I ) : [7]

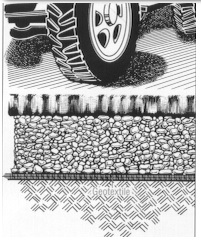

Wet soil conditions in animal feeding and high-traffic live-stock handling areas cause problems for both animals and producers, as well as the environment. Ruminating animals, such as beef, dairy, and sheep, often concentrate at stream crossings, in paddock lanes, and in feedlots and barnyards. In association with animal production, there will be concentrated farm vehicular and equipment traffic. When the animal and/or equipment traffic is excessively high, the vegetation is destroyed. During and after rainy weather, the soil in these areas turns to mud, creating an unhealthy environment for optimal livestock production, poor traction for farm equipment, and potentially poor surface water quality. Once these areas dry, they may provide rough and possibly hazardous footing for the animals.

After the vegetation in these concentrated areas is destroyed, the soil is bare and subject to erosion. In addition, once wet soil that has been trampled by livestock dries, it has a greatly reduced infiltration rate, and thus a much higher potential for producing runoff of soil and manure. Both of these conditions are conducive to creating a water quality problem. However, all of the conditions summarized above cause problems for producers as they try to properly manage the many operations for a profitable livestock production system.

The use of geotextile fabric in these high-traffic livestock areas can substantially reduce the occurrence of adverse conditions (see Figure 1). The installation of geotextile fabric combined with gravel can help provide a proper surface that animals, humans, vehicles, and equipment can travel on, and can also provide an erosion control benefit.

The purpose of this publication is to help producers, landowners, and agency and industry personnel who work with producers and landowners, understand the proper application, installation, and maintenance of geotextile fabric for agricultural applications. This publication provides an overview of a demonstration project (Using Geotextile Cloth in Livestock Operations to Reduce Nutrient and Sediment Loading in the Olentangy Watershed) on the use of geotextile fabric in high-traffic livestock areas. Some of the material provided is based on cooperative agency-industry-producer experiences from twelve project sites constructed in Morrow County, Ohio, during 1994.

Figure 9-1. Illustration of a site before geotextile fabric application (Left) and Fig 9-2 a similar site after application of the geotextile fabric (Right).[7]

Case ( II ): [8]

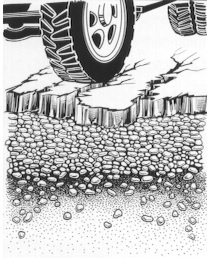

The leading cause of pavement and roadway failure in the U.S. is contamination of the aggregate base and the resulting loss in aggregate strength. When aggregate is placed on a subgrade, the bottom layer becomes contaminated with soil. Over time, traffic loading and vibration punches pavement base aggregate into the soil and causes silt and clay to migrate upward. On wet sites, construction traffic causes pumping of weak subgrade soils into overlying aggregate. All of these conditions decrease the effective aggregate thickness destroying the road support and reducing roadway performance and life.

Fig.10-1.2 Illustration of with ( Fig10-1 ) and without ( Fig10-2 ) geotextile [8]

Figure 10-1

Figure 10-2

Reference:

- Robert M. Koerner

Designing with Geosynthetics

, 1998 - (http://www.drexel.edu/gri/gmat.html

- John N.W. M

Geotextile

, 1987 - TANFEL Advertisement report 1990

- http://www.geofabrics.com.au/bidim.htm#filtration

- http://www.geofabrics.com.au/bidim.htm#embankment

-

http://www.ag.ohio-state.edu/~ohioline/aex-fact/0304.html

- http://www.acf-environ.com/stabprod.html

- http://www.cofra.com/typar.html

Apparel Search

Add Your Company Contact

Us About Us Advertise

News Letter Legal

Help

Copyright ©

1999-2023 Apparel Search Company.

All Rights Reserved.

Buy Fashion

For The Holidays.